Now that “The Phallus of AGILE” is well past 200 pages with the framework of the content in place I poked around today doing a search for the lowest priced POD (Print on Demand) service. I decided to put the worst case scenario to the test. A second edition of my OpenVMS book (might be taking a new OpenVMS contract soon and with the upcoming release on the x86 hardware it is possible I might choose to finish the second edition if the first edition “sells out.”)

For the second edition I was wanting to use a color interior. Instead of black on grey for listing highlights I could actually use the traditional yellow highlight and color screen shots.

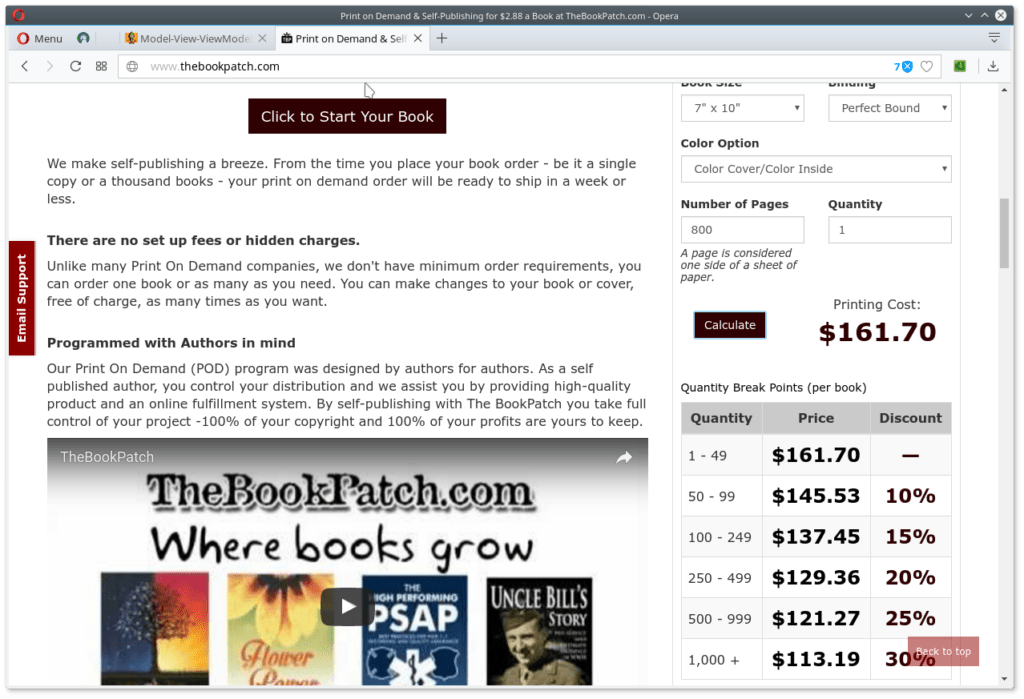

Look at that price! And that is the printing cost!!! I would have to sell it for twice that to make any money at the 65% retailer discount path.

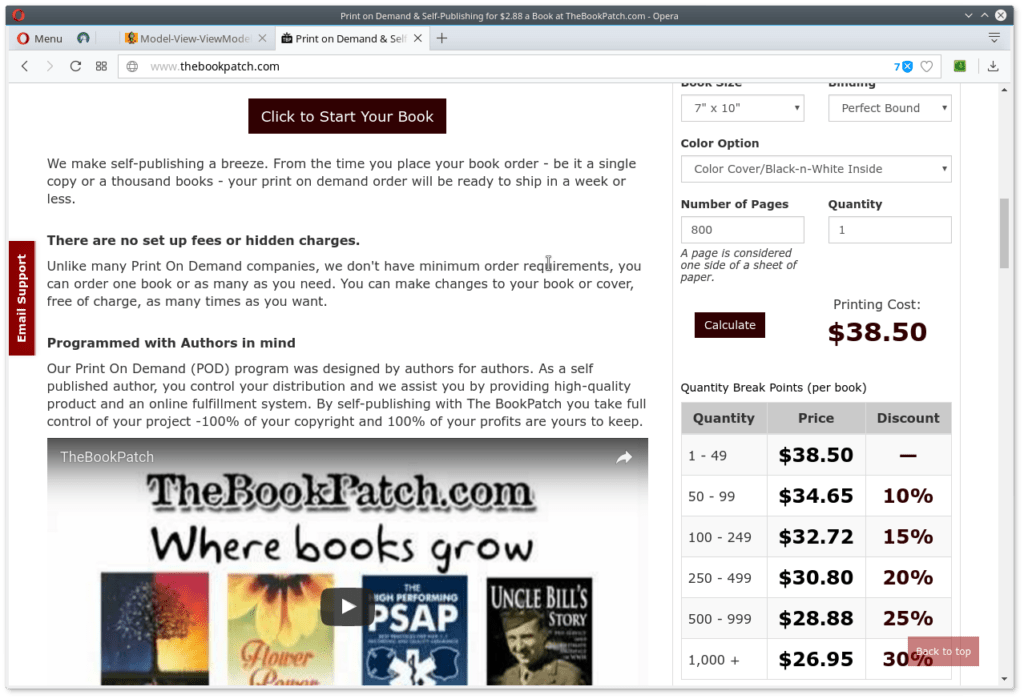

Don’t worry, their black & white prices are just as horrible as Ingram Spark.

Such father rapers! Offset press was about 1/3 of that.

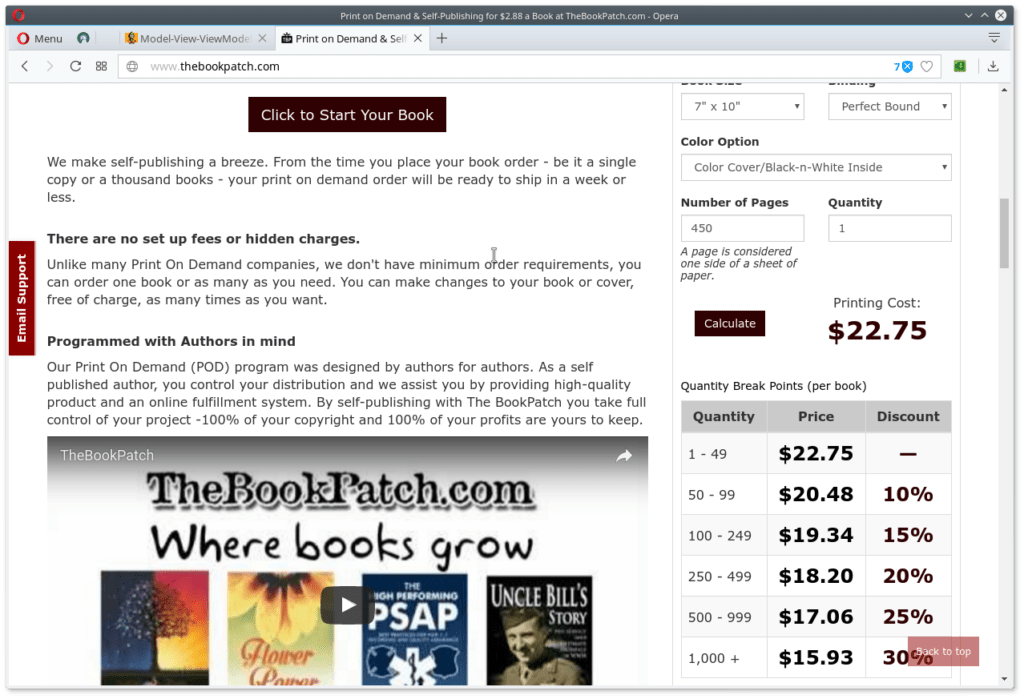

“The Phallus of AGILE” should weigh in around 450 pages. Books of this type tend to list for around $35.

Unreal! They want $17.06/copy for a 500+ unit print run. You will notice the price does not drop significantly at 1,000 and never drops again.

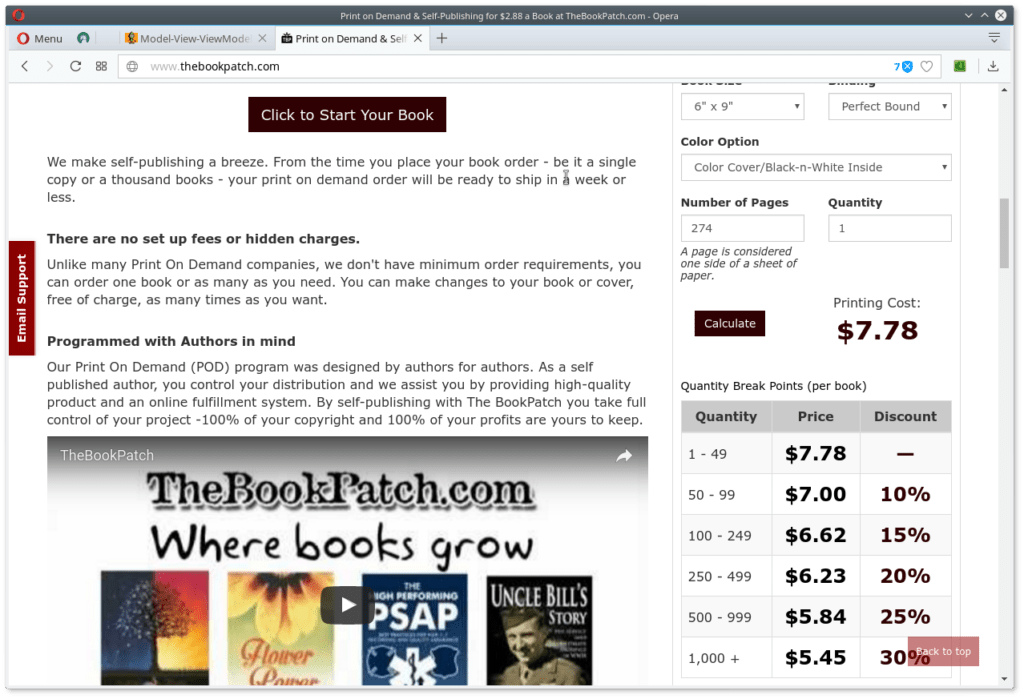

You will note that these are all 7×10 books. The “standard” size for IT books. The last book I physically printed was “John Smith.” I can’t believe that was back in 2010, but it was. I did a print run north of 1000. Can’t find the PDF with the quote but have around 700 copies on a pallet at last count so definitely well north of 1000. Might have been 1700. At any rate, with freight shipping the print run total was $7,372.9 so if it was only a 1000 unit run: $7.3729/copy. I was rather shocked to conduct the 6×9 experiment for 274 pages.

This is the dirty little secret most authors don’t know or refuse to hear no matter how many times a woman tells them:

size matters

Every POD or real print shop will “offer” many sizes, but they are only setup to really do a couple well. You find this in your quotes. I ran an 800 page 6×9 on here just for grins and 1,000 units came in at $13.89 and the one unit run $19.84. (How Orwellian!) The difference in paper and ink does not account for the dramatic difference in price between 6×9 and 7×10. This is a shop which “offers” it but isn’t set up to handle it so there is a much higher labor cost involved.

An offset/Web press run will _always_ be cheaper on a per unit basis for a print run of “sufficient” size. If a print shop is actually set up to handle your sized work you will find a sweet spot somewhere north of 1,000 units where the per unit cost stops dropping percipitously. This is where you have completely consumed the setup cost of a print run and will only get minor cost improvements until they reverse and start going up. While the expensive and heavy copper plates of yesteryear could print upwards of 1 million copies before impression quality went too low, the short run direct-to-plate things tend to fail somewhere south of 5,000 copies. This isn’t a bad thing. Their customer base tends to be buying print runs of 500 to 2,000 copies. You need to know this though because once you cross the life span boundary of the plates you will incur another setup charge or at least a partial charge. You “might” get lucky and they will etch/stamp 2 sets of plates during the initial setup.

In summary:

You have to shop around. Yes, asking for quotes and filling out the RFQ (Request for Quote) forms is a pain. The on-line quote calculators tend to always have a higher price. Most aren’t adjustable for current work load. When a print shop is busy you get the “I don’t want your business” really high quote. When presses are sitting idle and they are faced with laying people off you get the “we’re starving” quote.

Printing prices tend to be lower in February and March and dramatically higher from October through the end of year as everyone is trying to print inventory for the holiday market. January is an iffy month for quotes. It depends on how much they abused the printing equipment at the end of the year to make all of that “holiday cash.” The entire place may be shut down for weeks while maintenance crews undue the damage.

Not all POD services will list your book with a distributor or provide access to any major sales channel. Some are just off-shoots of traditional print shops. They print and ship to you. They “might” offer to sell it on their own Web site, but, you’ve probably never heard of that site, so don’t expect that to be a sales channel. Part of the printing fee is the additional distribution services.

Size matters! Don’t be ashamed to ask a print shop what their “preferred” or “most common” dimensions are. These will have the lowest labor cost as the shaker, cutter and binder for those sizes will be staged in close proximity if not in a continuous sequence. Other “supported” sizes will have to be stacked on pallets and hauled over to the equipment which can handle those sizes. Usually there is one set of equipment which handles the “other” sizes and it has to be continually reset/resized for each job.

How many of you actually thought about the trim size of your book before you started writing? It is the single most important decision you can make. It impacts both the production cost and number of pages.

One of the main reasons I and many others write “final copy” in our word processors instead of the archaic “manuscript” form is so when our final edit is done the book is done. The running page headers, table of contents, footers, etc. It was all there during the edit process. We really are ready for a print run. I let the ebook conversion service strip all of that out.

It is easier to strip than to add.

Question: How many times have you purchased a book and noticed a typo or spelling error in the TOC (table of contents) or a running page header? This is a red flag. The book was created via the archaic “manuscript” format. After the edit process, all of that stuff got added.